Power Your Precision with CNC Machine Fanuc Control

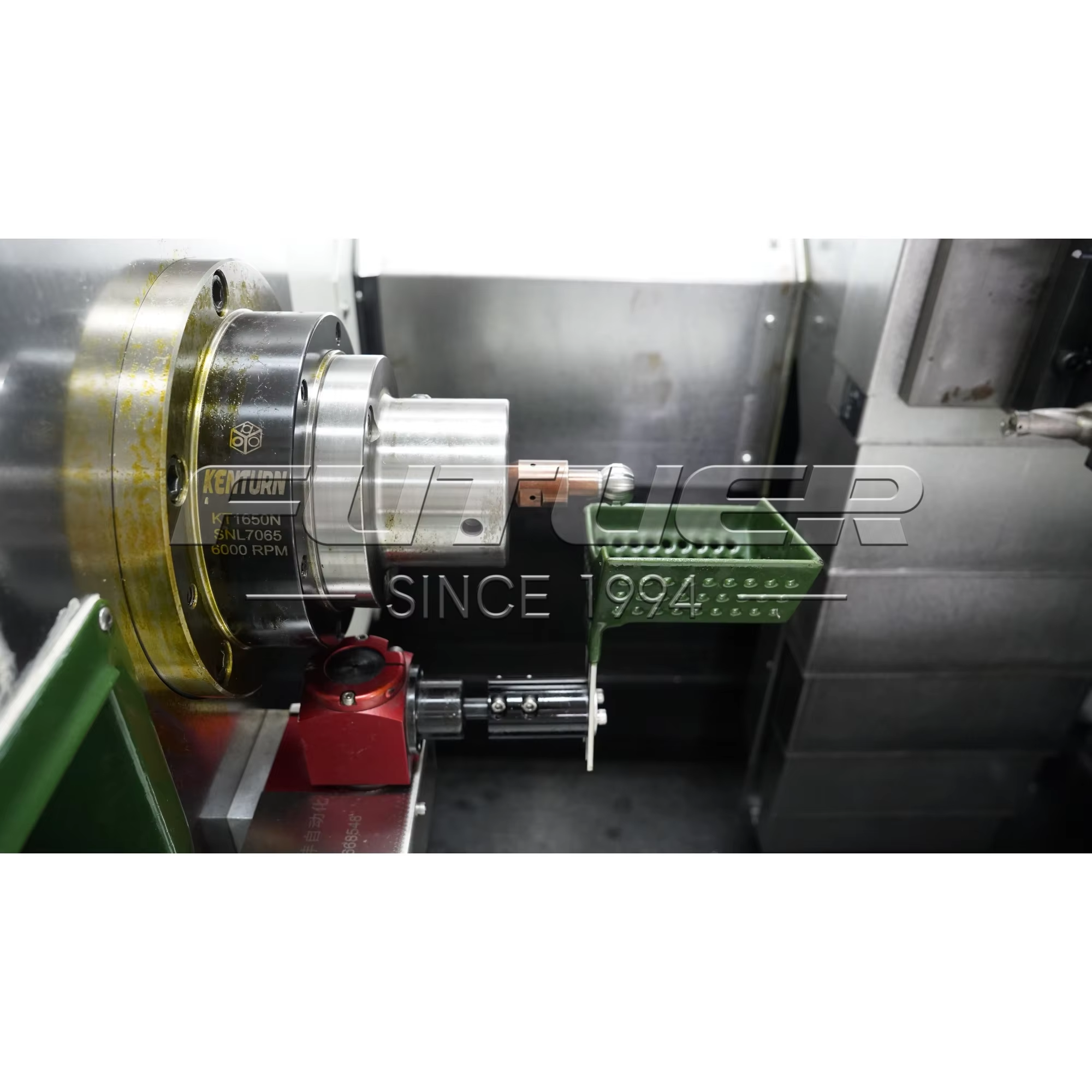

CNC machines equipped with Fanuc controls represent the industry standard for reliability and precision across global manufacturing sectors. These robust control systems are deployed in automotive factories producing engine components, aerospace facilities machining structural airframe parts, and medical device manufacturers creating implantable components. The universal compatibility of Fanuc controls with both turning centers and machining centers makes them indispensable for high-volume production of shafts, brackets, gears, and housings where consistent quality and minimal downtime are critical to maintaining production schedules and meeting stringent industry specifications.

The application scope of Fanuc-controlled CNC machinery expands significantly into complex manufacturing operations through advanced programming capabilities and multi-axis functionality. Manufacturers leverage these systems for sophisticated tasks including 5-axis simultaneous machining of aerospace impellers, precision boring of medical device molds, and high-speed hard milling of injection molds. The controls' advanced features—such as thermal compensation, vibration suppression, and adaptive feed rate control—enable precision machining of difficult materials like titanium alloys and composites, while custom macro B programming allows for family-of-parts manufacturing and specialized cycle development for complex geometries.

Looking toward the future of manufacturing, Fanuc-controlled CNC machines are evolving into integrated smart factory solutions with built-in Industry 4.0 capabilities. Modern Fanuc systems feature IoT connectivity through MT-LINKi and FIELD system integration, enabling real-time monitoring of machine performance, predictive maintenance alerts, and production data analytics. This connectivity transforms individual machines into data-rich nodes within digital manufacturing ecosystems, supporting remote diagnostics, tool life management, and energy consumption optimization. For manufacturers investing in long-term competitiveness, Fanuc-controlled equipment provides a proven pathway to automated cells, lights-out manufacturing, and data-driven process optimization across the production floor.

Copyright © GUANGDONG FUTUER GROUP CO.LTD — Privacy Policy