The tooth-row type feeding structure does not require adjustment when changing materials, making it suitable for micro-sized material processing. It can be optionally equipped with an electronic synchronizer, which is suitable for high-speed processing by centerless grinding machines. It adopts pulse data control, allowing the cutting end of the first sample of the material to be stably controlled within 0.20mm. At the same time, material replacement can be completed within 15 seconds. Electrical and mechanical faults can be diagnosed by oneself, and maintenance is simple and quick. During the processing, if the rod breaks or the cutting tool is damaged, an immediate alarm and shutdown can be triggered. It reduces energy consumption and tool wear. The tool life can be managed, and the material usage and production capacity can be statistically recorded, facilitating quality control and operation management.

MACHINE DETAILS

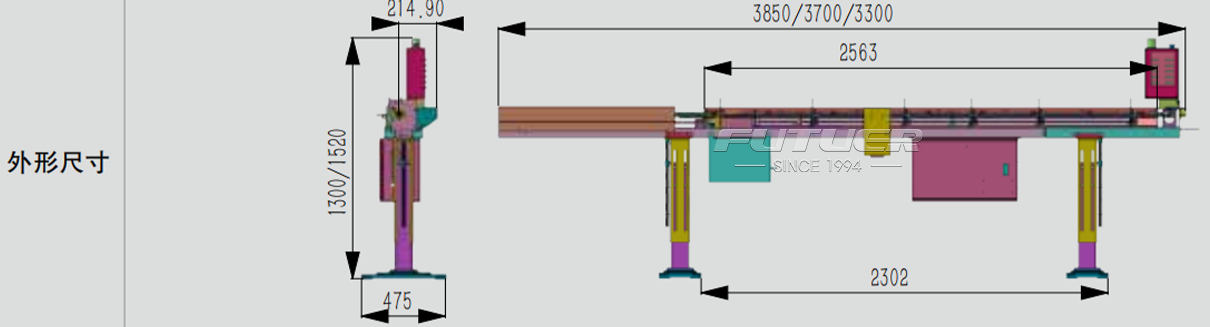

Equipment details and standard size related parameters

| Project | CT/N-06 | CT-12 | |

| Working ability | Bar machining maximum diameter | Φ5mm | Φ12mm |

| Bar machining minimum diameter | Φ0.8mm | Φ1.2mm | |

| Length of the bar machining | 2500mm | ||

| The silos activities range | Φ6.3mm | Φ8.5mm | |

| Other |

Material capacity | 20pcs | 20pcs |

| Required eiectric power | 0.46kw | ||

| Mass of machine | Approximately 216kg |

||

| Power | 50-60Hz | ||

FUTUER GROUP

About Guangdong Futuer Machinery Co., Ltd.

Copyright © GUANGDONG FUTUER GROUP CO.LTD — Privacy Policy