The silo is of a fully sealed structure, combined with ultra-high molecular polyethylene. The material transportation is noise-free and avoids scratches. It can handle flat, square, triangular or quadrangular and other irregular materials, as well as materials with a diameter of about 2 mm. It has a high cost-performance ratio. It adopts pulse data control, and the cutting end of the first piece of material can be stably controlled within 0.20 mm. With PLC and servo, touch screen control, it is data-driven and easy to operate. Electrical and mechanical faults can be diagnosed by themselves, and maintenance is simple and quick. It can manage the tool life, count the materials and production capacity, which is convenient for quality control and operation management.

MACHINE DETAILS

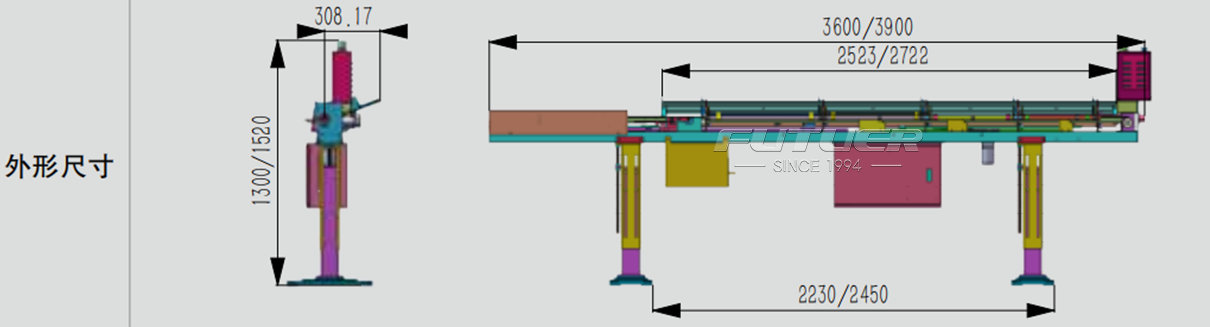

Equipment details and standard size related parameters

| Project | CT-08 | CT-10 | |||

| Working ability | Bar machining maximum diameter | Φ7mm | 4×6 flat material or irregular-shaped materials with an edge length of 7.5 mm or less | Φ10mm | 4×8 flat material or irregular-shaped materials with an edge length of 9.0 mm or less |

| Bar machining minimum diameter | Φ1.8mm | Φ2mm | |||

| Length of the bar machining | 2500mm |

||||

| The silos activities range | Φ9mm | Φ11mm | |||

| Other |

Material capacity | Φ3×68pcs Φ10×25pcs | 60pcs | Φ4×51pcs Φ15×15pcs | 60pcs |

| Required eiectric power | 0.61kw |

||||

| Mass of machine | Approximately 205kg |

||||

| Power | 50-60Hz |

||||

FUTUER GROUP

About Guangdong Futuer Machinery Co., Ltd.

Copyright © GUANGDONG FUTUER GROUP CO.LTD — Privacy Policy