Using pulse data control, the cutting end of the first sample piece of the material can be stably controlled at 0.2mm; with PLC and servo, touch screen control, data-based operation, it is extremely easy to operate; electrical and mechanical faults can be diagnosed by themselves, and maintenance is simple and quick; during the processing, if the bar is ejected or the cutting tool is damaged, an immediate alarm will be triggered and the machine will stop; it reduces energy and tool wear; it can count the processed products and materials, which is convenient for on-site operation management; it can perform fixed-number processing of the products, which is convenient for quality control; the material change is fast and the adjustment is convenient.

MACHINE DETAILS

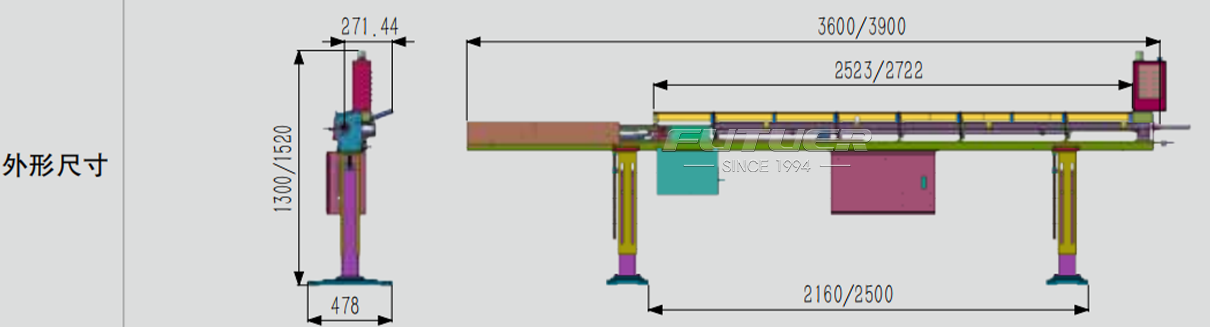

Equipment details and standard size related parameters

| Project | CT-08 | CT-12 | CT-16 | CT-20 | |

| Working ability | Bar machining maximum diameter | Φ8mm | Φ12mm | Φ15mm | Φ20mm |

| Bar machining minimum diameter | Φ3mm | Φ4mm | Φ5mm | Φ6mm | |

| Length of the bar machining | 2500mm-3000mm | ||||

| The silos activities range | Φ9mm | Φ13.5mm | Φ16.5mm | Φ23mm | |

| Other |

Material capacity | Φ8×35pcs | Φ12×23pcs | Φ15×18pcs | Φ20×14pcs |

| Required eiectric power | 0.46kw | ||||

| Mass of machine | Approximately 460kg |

||||

| Power | Approximately 195kg | ||||

FUTUER GROUP

About Guangdong Futuer Machinery Co., Ltd.

Copyright © GUANGDONG FUTUER GROUP CO.LTD — Privacy Policy