Core Design and Functional Differences Between CNC Turning Centers and Traditional Lathes

Fundamental Distinctions in Design and Operation Between CNC Turning Centers and Traditional Lathes

| Feature | CNC Turning Center | Traditional Lathe |

|---|---|---|

| Control System | Automated CNC Programming | Manual/Mechanical Control |

| Axis Mobility | Multi-axis (X, Z, Y, C, B) | Typically 2-axis (X, Z) |

| Precision Tolerance | ±0.0002" (ISO 2768-f) | ±0.002" (Skilled Operator) |

| Operator Dependency | Minimal after initial setup | Constant supervision |

Structural Layout and Mechanical Configuration: CNC Lathe vs Turning Center

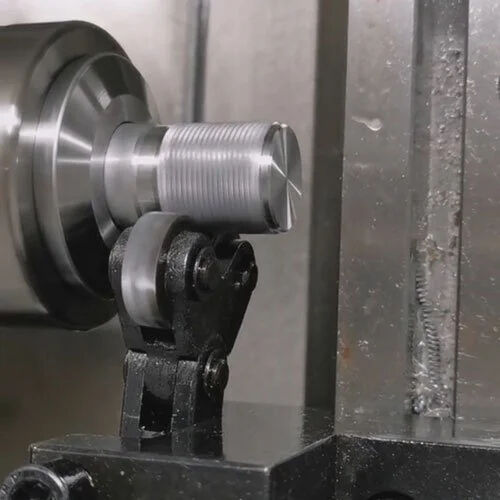

CNC turning centers feature enclosed workspaces with integrated chip conveyors and coolant systems, unlike the open-bed designs of traditional lathes. This design supports continuous 24/7 operation in demanding environments while shielding critical components from debris and contamination.

Axis Configurations (X, Z, Y, C, B) and Their Impact on Machining Capabilities

The inclusion of a Y-axis enables off-center drilling and contouring–capabilities absent in standard 2-axis lathes. With live-tool C-axis control (rotational positioning) and B-axis (angled tool movement), CNC turning centers can complete complex geometries such as helical gears and multi-plane threads in a single setup, eliminating secondary operations.

Precision, Repeatability, and Performance in High-Demand Applications

Accuracy and Consistency in CNC Turning vs Manual Lathes Under Real-World Conditions

Modern CNC turning centers can hold tolerances as tight as ±0.001 mm according to ISO standards from 2022, thanks to their closed loop feedback systems. This is way better than what manual lathes typically achieve, which usually have around ±0.02 mm variation when making parts in real workshop conditions. People get tired, eyesight isn't perfect all day long, and measurements just aren't consistent over time - these human elements naturally lead to bigger errors in manual work. Looking at actual production numbers from a 2023 study helps put this into perspective. When they made 1,000 identical brass fittings, the differences between parts produced on manual lathes versus CNC machines was actually about 4.5 times greater. That kind of discrepancy matters a lot when quality control becomes an issue for manufacturers.

Repeatability Advantages of CNC Turning Centers in High-Volume Production

CNC systems have pretty much nailed repeatability at around 99.8%, according to NIST data from 2023. This kind of precision matters a lot in industries like aerospace and medical device manufacturing where every part needs to match exactly. After initial programming, these machines keep producing components within just 2 microns of tolerance specifications across tens of thousands of production cycles without needing any operator input. Human machinists? Even the best ones struggle to maintain consistency better than plus or minus 5 microns when working on batches smaller than 50 pieces. A recent look at precision manufacturing practices on LinkedIn back in 2024 showed something interesting too: factories using CNC technology saw their waste materials drop by nearly two thirds during large scale production runs versus traditional hand machining approaches.

Can Traditional Lathes Still Achieve Tight Tolerances? Evaluating Viability

Old school lathes are still pretty good at holding around 0.01 mm accuracy which makes them workable for prototypes and small production runs. But let's face it, setting these machines up takes about 38% longer than their modern counterparts according to Tooling U-SME data from last year. Many specialty shops stick with manual lathes when restoring classic cars or making one-off parts. About seven out of ten such workshops report getting decent results from hand operated machines. That said, most companies following strict ISO 2768 quality standards tend to move away from manual methods as soon as volume increases. The numbers tell the story pretty clearly here – just 9% of certified manufacturers make manual turning their go-to approach because scaling production becomes problematic with traditional equipment.

Production Efficiency and Automation Capabilities of CNC Turning Centers

Automation Features That Enhance Productivity in CNC Turning Centers

Today's CNC turning centers come equipped with robotic part handling systems and automatic tool changers, which cut down on idle time significantly when compared to traditional manual lathes. According to recent industry reports from 2023, these machines can reduce downtime anywhere between 40% to 60%. The multi-axis setup is particularly impressive because it allows for turning, milling, and drilling all at once. This means manufacturers can produce intricate parts like those used in aircraft engines or orthopedic devices without having to stop and reposition the workpiece multiple times during production. Some of the newer advanced models now feature AI based collision detection systems along with smart cutting algorithms that adjust feed rates on the fly. These innovations have been shown to shorten overall machining cycles by around 22% to 35%, especially important for high precision manufacturing where every second counts.

Labor Requirements and Reduced Dependency on Highly Skilled Operators

According to recent workforce data from 2024, companies using CNC turning centers report cutting direct labor expenses by about 58% compared to old school lathe work. The technology behind these machines is pretty impressive too. With gantry loaders and those bar feed systems, a single worker can actually watch over three to five different machines at once. Plus, the built-in probing systems mean there's far less need for hands-on quality checks throughout the process. Traditional lathes tell another story entirely though. They require workers with specific expertise just to handle basic tasks such as adjusting tapers or chasing threads properly. These specialized operations alone eat up around 34 cents out of every dollar spent on production when automation isn't part of the equation.

Setup Complexity and Operational Efficiency Across Both Machine Types

| Parameter | CNC Turning Center | Traditional Lathe |

|---|---|---|

| Average Setup Time | 15-45 minutes | 2-4 hours |

| Tool Presetting | Automatic | Manual |

| Error Rate (First Part) | ±0.005mm | ±0.03mm |

| Changeover Frequency | 2x/day | 5x/day |

While CNC systems require upfront CAM programming (6–12 hours per part family), they deliver over 85% operational efficiency in high-volume production via lights-out manufacturing. Traditional lathes have lower initial setup costs but incur 28% longer machining times for batches exceeding 50 units, according to a 2023 automotive components study.

Cost Considerations: Initial Investment, Maintenance, and ROI Analysis

Total Cost of Ownership: Setup, Operation, and Maintenance Over a 5-Year Lifecycle

Traditional lathes definitely have a lower upfront cost, typically ranging from around $50,000 to $150,000 compared to CNC turning centers which can set manufacturers back anywhere between $200,000 and even $700,000. But when looking at what these machines actually cost to run over time, the picture changes quite a bit. The manual versions end up costing roughly twice as much in labor expenses because they take so much longer to complete jobs and require operators to constantly monitor them. CNC systems make up for their steeper initial investment in several ways though. They produce significantly less waste material, sometimes under 1% compared to 3% or 5% with traditional machines. Plus there's all those fancy features like predictive maintenance that keeps machines running smoothly 40% more than before, plus smart spindle controls that actually save on electricity when the machine isn't actively cutting parts.

Return on Investment for CNC Turning Centers in Mid-Volume Manufacturing Environments

Manufacturers making between 500 to 5,000 parts each year often see their CNC turning centers pay for themselves in around 18 to 30 months. This happens because these machines can run without constant supervision and the tools last longer when properly maintained. A medium sized aerospace company actually saw a return on investment of about 22% after switching over to CNC technology. They attributed this mainly to being able to produce parts around the clock and having built in systems that automatically check quality standards. That said, smaller operations dealing with lots of different designs or those only producing under 200 parts per year might still prefer traditional manual lathes. The time spent programming CNC machines for small batches just doesn't always make financial sense compared to what they save in other areas when volumes are really low.

Versatility and Advanced Machining Features in Modern CNC Turning Centers

Live Tooling and Multi-Tasking Capabilities for Complex Part Fabrication

CNC turning centers today come equipped with live tooling that lets them do milling, drilling, and tapping while the part is still spinning, so there's no need to take it out of the machine. The ability to handle multiple tasks at once can cut down production time quite a bit for complex items such as valve bodies or hydraulic fittings maybe around 35-40% depending on what exactly needs making. These advanced machines combine both rotational movement and precise cutting paths to produce completely finished parts all in one go something regular lathes just cant do. Manufacturers find this particularly valuable when dealing with tight deadlines or custom orders where every minute counts.

Multi-Axis Machining and Its Role in Producing Intricate Geometries

Modern CNC turning centers equipped with 5 or even 7 axes can do things regular 2-axis lathes simply cannot handle. They machine those tricky undercuts, complex curves, and all sorts of asymmetrical shapes without needing multiple setups. Take automotive turbocharger impellers as an example these parts need really tight tolerances around plus or minus 0.005 mm. The machines synchronize their Y and C axes to get this job done right. What's impressive is how smooth the finished surfaces turn out sometimes better than Ra 0.8 microns roughness. That means manufacturers save time and money because they don't have to go back for extra grinding work after the fact.

Spindle Configurations: Single, Dual, and Sub-Spindle Setups for Flexible Production

Dual spindle CNC turning centers can actually increase production output somewhere around 60 to 70 percent when compared with traditional single spindle machines because they let operators machine both sides at once. The sub spindle system handles transferring parts automatically so everything gets done from start to finish without needing manual intervention. This makes these machines particularly good for things like surgical implants where precision matters or those tiny but critical aerospace components. Modern day spindle designs are getting pretty flexible too. Most shops report being able to switch between torque heavy setups that handle up to 450 Newton meters and super fast ones spinning at 12 thousand RPM within just about fifteen minutes flat.

Tooling Systems Comparison: Live Tooling, Fixed Turrets, and Automatic Tool Changers

Today's CNC turning centers come equipped with these impressive 24 station live turrets paired up with automatic tool changers that can actually hold more than 120 different tools. What does this mean? Changeover times drop down below those 90 second marks we all love hearing about. Traditional setups with their fixed turrets just cant compete really, since they only give operators around 12 tools to work with. And let's not forget how modern CNC machines have robotic arms built right in to swap out those worn inserts halfway through production cycles. This keeps product quality steady even when running thousands of pieces straight through. Speaking of improvements, live tooling has made big strides lately too. The new HSK-63 interfaces are making quite a difference, giving shops about 30 percent more rigidity when tackling those tough heavy duty milling jobs that used to shake things apart so easily.

Frequently Asked Questions

What is the main advantage of CNC turning centers over traditional lathes?

The primary advantage of CNC turning centers is their automation capability, which reduces the need for constant operator supervision and increases productivity by handling complex geometries and enabling multi-axis machining.

How do CNC turning centers impact production efficiency?

CNC turning centers enhance production efficiency by incorporating features like robotic part handling, automatic tool changers, and AI based collision detection systems, which significantly reduce downtime and machining cycle times.

Are traditional lathes still relevant in modern manufacturing?

Though traditional lathes are still useful for prototypes and small production runs, they are less efficient than CNC machining for high-volume production due to longer setup times and lower precision.

Table of Contents

- Core Design and Functional Differences Between CNC Turning Centers and Traditional Lathes

- Precision, Repeatability, and Performance in High-Demand Applications

- Production Efficiency and Automation Capabilities of CNC Turning Centers

- Cost Considerations: Initial Investment, Maintenance, and ROI Analysis

-

Versatility and Advanced Machining Features in Modern CNC Turning Centers

- Live Tooling and Multi-Tasking Capabilities for Complex Part Fabrication

- Multi-Axis Machining and Its Role in Producing Intricate Geometries

- Spindle Configurations: Single, Dual, and Sub-Spindle Setups for Flexible Production

- Tooling Systems Comparison: Live Tooling, Fixed Turrets, and Automatic Tool Changers

- Frequently Asked Questions