Core Design Elements That Enable Precision in Every CNC Turning Machine

What makes a high precision CNC turning machine work so well starts with how stable it is mechanically. Getting those IT5 to IT7 tolerances consistently requires something really rigid that won't bend when subjected to cutting forces. Most good machines have heavy cast iron frames along with hydrostatic guideways as their base structure. These parts help soak up vibrations and can handle pretty serious loads, sometimes upwards of 12,000 Newtons. Thermal stability matters just as much though. When things get hot during operation, metal expands and this can actually move the position by over 10 micrometers per meter if nothing is done about it. The best CNC machines now come with built in cooling channels right inside the spindles and ball screws. They also run these smart algorithms that constantly adjust for temperature changes, bringing down positioning errors to below 5 micrometers per meter even after long running periods. Putting together solid construction with clever temperature control gives these machines the ability to maintain dimensional accuracy under 10 micrometers repeatedly. This kind of performance is what industries need for making parts in aerospace applications, medical implants, and all sorts of precision optical components where tiny differences matter a lot.

Machine Rigidity and Thermal Stability for IT5–IT7 Tolerance Consistency

Geometric Integrity: Controlling Roundness, Cylindricity, and Axial Runout (<0.005 mm)

When it comes to machine components, geometric perfection goes hand in hand with how well they actually function. Angular contact spindle bearings that can adjust their preload help reduce radial errors so roundness stays within just 0.005 mm tolerance. For those working on face machining operations or aligning bores, controlling axial runout becomes absolutely essential. That's why manufacturers rely on ground lead screws paired with roller nuts that eliminate any play between moving parts. To check if these components meet the required standards, companies perform laser interferometry tests along with ballbar assessments according to ISO 230-6 specifications. These tests confirm that cylindrical surfaces stay within plus or minus 1.5 micrometers over standard production runs. Tool holders made from either hydraulic systems or shrink fit designs prevent deflection at the cutting tip, making sure what gets programmed into the machine translates accurately onto the finished product. Parts that require tight seals such as hydraulic valve spools or fuel injector nozzles demand this kind of precision because even tiny manufacturing errors can lead to major problems down the line when systems start failing prematurely.

Surface Finish and Toolpath Optimization in CNC Turning Machines

Achieving Ra 0.4–1.6 μm via Adaptive Feed Rates and High-Fidelity Tool Geometry

Getting surface finishes in the Ra 0.4 to 1.6 micrometer range demands tight coordination between cutting mechanics, tool condition, and immediate feedback from the machine. Adaptive feed rate technology keeps track of spindle load and makes on the fly adjustments to cutting speeds so chips form consistently. This helps avoid problems like chatter and those annoying vibrations that create rough spots, particularly important when working with tough materials like hardened steel rated at HRC 58 to 62 or delicate thin wall sections. These systems actually fix issues caused by material differences that used to make surface finishes vary by more than plus or minus 0.2 micrometers. High quality tooling plays its part too. Tools with edges honed down below 5 micrometers and coated with TiAlN significantly cut down on built up edge while making sure the metal shears evenly during cutting. When manufacturers prepare edges at the micro scale level, they see around 30 percent improvement in reducing those peaks and valleys compared to regular inserts. All these methods combined produce surfaces so smooth they look like mirrors, eliminating the need for extra finishing steps. This directly improves how well parts seal and function in bearing applications. Industry reports show manufacturing plants are seeing about 18 to 22 percent faster finishing times without sacrificing consistent quality throughout their production runs.

Automation-Driven Efficiency: From G-Code to Real-Time Throughput Gains

Auto-Tool-Changing Turrets and Intelligent Cycle Time Reduction (Up to 40%)

Automatic tool changers, or ATCs as they're commonly called, take away the need for workers to manually switch tools during machining processes. This means machines can run continuously without stopping for operator input. Take modern turret systems for instance these days they swap tools in less than 10 seconds flat. That cuts down on downtime between operations and can actually shorten entire production cycles by around 40 percent. What's more impressive is how accurate they stay too, maintaining position within about 0.005 millimeters even after countless repetitions. The latest systems come equipped with built-in vibration sensors that keep track of when tools start wearing out. When detected early enough, machine controllers will automatically tweak feed rates so parts still meet specifications despite the gradual loss of cutting edge sharpness. For manufacturers dealing with intricate shapes and large volume orders, this combination of smart hardware and software makes overnight production runs possible without sacrificing product quality standards.

G-Code Optimization Techniques That Preserve Accuracy While Maximizing Output

Strategic G-code programming minimizes non-cutting movements through algorithmic path planning—compressing cycle times by 25–30% without sacrificing tolerance adherence. Key methods include:

- Adaptive clearing, which maintains constant tool engagement to prevent deflection-induced errors

- Peck cycle optimization, reducing chip recutting and improving chip evacuation in deep-hole drilling

- Nesting algorithms, grouping similar operations (e.g., all grooving passes) to minimize rapid traverses

Simulation software validates optimized programs pre-production, detecting collisions and verifying kinematic feasibility while preserving IT7-grade dimensional stability. Crucially, this approach ensures accelerated machining never compromises the Ra 0.8 μm surface integrity required for critical functional surfaces.

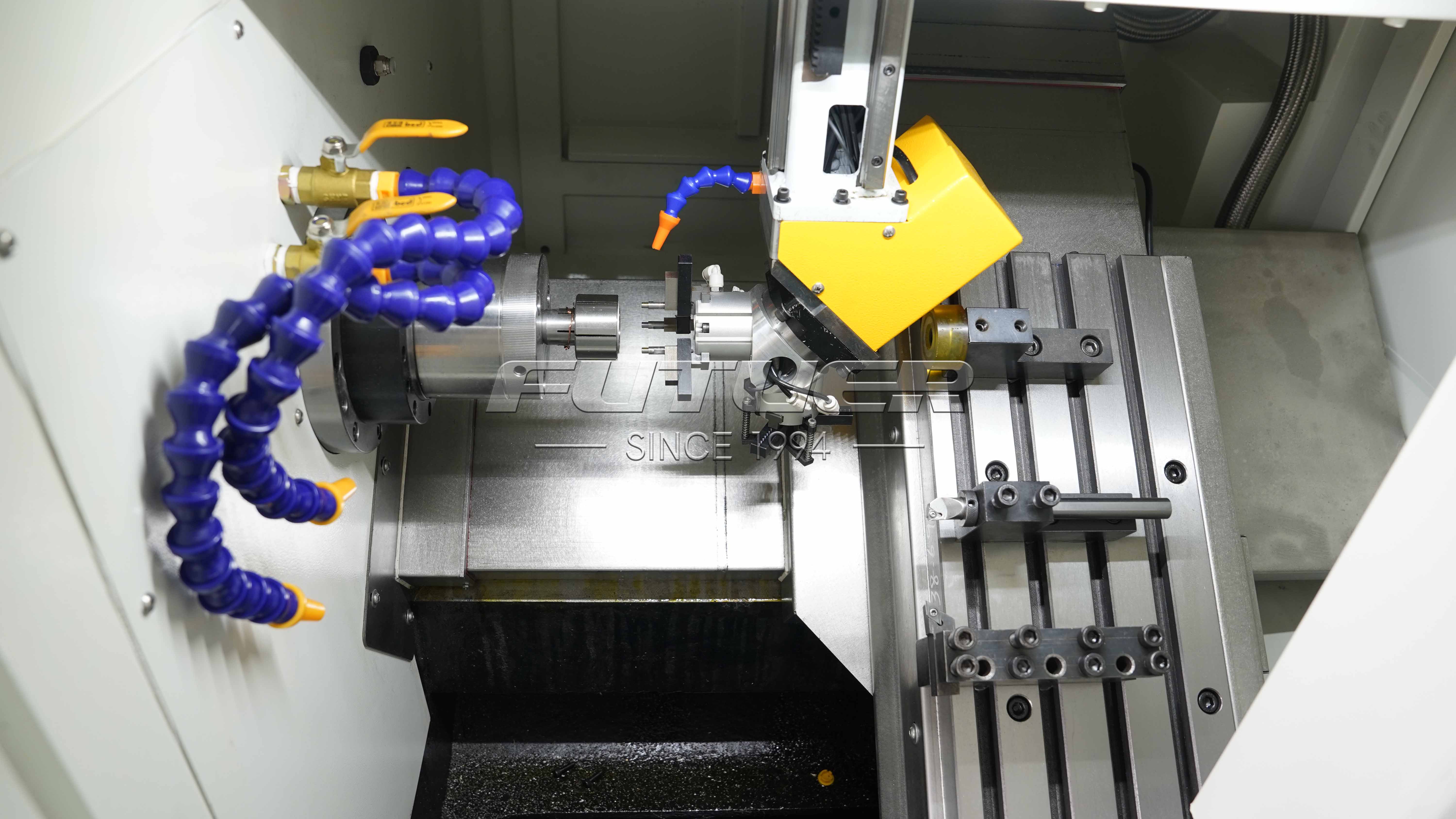

Critical Subsystems Defining CNC Turning Machine Performance

The precision and efficiency of a modern CNC turning machine hinge on the seamless integration of five interdependent subsystems:

- Motion control: High-resolution encoders (≡0.1 μm resolution), linear guides with pre-loaded recirculating rollers, and responsive servo drives enable micron-level tool positioning—directly governing dimensional accuracy and repeatability.

- Spindle assembly: Designed for thermal stability and dynamic balance, it sustains rotational speeds up to 6,000 rpm with <1.0 μm radial runout, preventing vibration-induced surface defects.

- Tool management: Automatic tool changers and rigid hydraulic/shrink-fit holders preserve tool-tip integrity and minimize setup variability across shifts.

- Workholding: Hydraulic chucks and high-precision collet systems deliver clamping forces exceeding 15,000 N with zero slippage—even during high-torque interrupted cuts.

- Cooling & lubrication: Closed-loop minimum quantity lubrication (MQL) systems combined with chilled coolant delivery mitigate thermal distortion, extend tool life by up to 40%, and support stable long-cycle machining.

These subsystems do not operate in isolation; their coordinated performance determines whether a machine consistently holds tight tolerances, achieves target surface finishes, and sustains reliability across thousands of production hours.

FAQ Section

What is the significance of thermal stability in CNC machines?

Thermal stability ensures that the metal components in CNC machines do not expand excessively when heated, maintaining precise positioning and performance. Built-in cooling channels and smart algorithms help minimize positional errors.

How do automatic tool changers improve CNC machine efficiency?

Automatic tool changers eliminate the need for manual tool switching, enabling continuous machine operation and reducing downtime, thereby increasing overall efficiency.

Why is achieving surface finish important in CNC turning?

A superior surface finish allows for better sealing and functioning of components, notably in bearing applications and similar critical uses, reducing the need for additional finishing processes.