Achieving Superior Precision with Single-Setup Multi-Axis Machining

Meeting Tight Tolerance Requirements in High-Precision Manufacturing

Modern industries like aerospace and medical device manufacturing demand tolerances under 0.001mm – a threshold only achievable through multi-axis CNC turning centers. These systems maintain positional accuracy across complex geometries by eliminating manual repositioning errors inherent in traditional 3-axis workflows, ensuring consistent precision on curved surfaces and deep pockets.

Reducing Cumulative Errors Through Minimized Handling and Repositioning

In traditional machining, every time parts get handled between steps, there's a risk of misalignment issues reaching about 0.005mm according to recent industry findings. That's where multi-axis machines come in handy. These systems handle around 95% of all operations while the part stays securely clamped, which keeps those important measurements consistent throughout. Looking at actual shop floor data, manufacturers have seen that when switching from standard setups to 5 or even 6 axis configurations, overall shape accuracy improves dramatically. The error rates drop by roughly two thirds compared to what happens with multiple separate machining steps. This makes a real difference in production quality, especially for complex components where precision matters most.

Case Study: Aerospace Component Production With Sub-0.001mm Tolerance Using a 6-Axis CNC Turning Center

One major player in aerospace manufacturing slashed their turbine housing cycle times by around 40% when they switched to using 6-axis CNC turning centers. These advanced machines handle those complex curved fuel nozzles with incredible precision - about 0.0008mm accuracy over 78 different sealing points. This level of control completely removed the need for any secondary grinding work and resulted in every single piece passing quality checks on the first try. What really makes this setup efficient is how everything gets done within just two hours from when the part is first clamped down. This quick turnaround helps avoid problems with heat buildup that typically occur during longer production runs, which can warp components and create costly rework situations.

Boosting Productivity by Reducing Setup Times and Workflow Interruptions

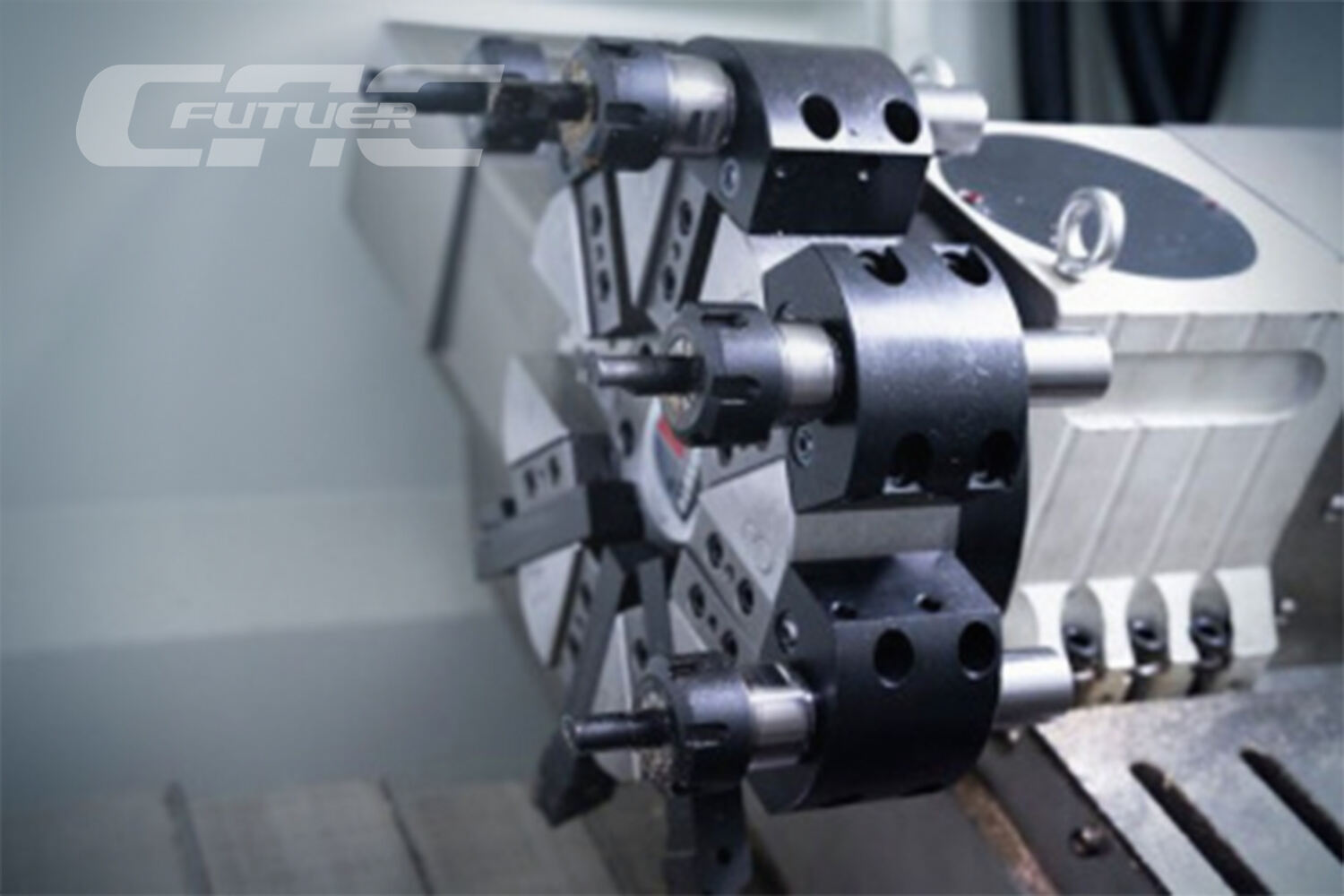

Fewer setups enabled by 5-axis capabilities and live tooling in CNC turning centers

The latest 5 axis CNC turning centers can produce intricate components from different angles all in one go, so there's no need to keep stopping and moving parts around manually. These machines come with built in live tools that let them do things like milling and drilling right alongside the main cutting process. A recent report on CNC machining from 2024 showed some pretty impressive results. Factories that switched to these advanced systems saw their setup times drop between 40 to almost 60 percent when compared to older 3 axis machines. What's even better? They managed to keep an incredibly tight tolerance of plus or minus 0.005 mm throughout the whole operation. This kind of efficiency makes a big difference in production environments where every minute counts.

Quantified gains: Up to 50% reduction in cycle and lead times in automotive applications

Car part manufacturers are seeing cycle times jump by around 45 to 50 percent for mass produced items like turbocharger casings and transmission rods when using those fancy multi-axis CNC turning machines. The real win comes from cutting down on how often parts need to be touched during production, which knocks out roughly 12 to 18 minutes of downtime between setups while also preventing those pesky alignment issues that pile up over time. A major supplier recently slashed their lead times by nearly half for electric vehicle motor parts once they brought in these advanced 7-axis turn-mill systems equipped with automatic pallet changers. Makes sense really, since every minute saved adds up across thousands of units rolling off the line each month.

Balancing initial investment against long-term efficiency and ROI

While multi-axis CNC systems carry a 20–35% higher upfront cost than conventional models, most manufacturers recoup the investment within 18–24 months through measurable efficiency gains:

- 30–40% lower labor costs per part

- 15–25% reduced scrap rates due to fewer setups

- 80–90% faster retooling for mixed-production batches

The operational flexibility of advanced CNC turning centers also future-proofs production lines, making them well-suited for evolving demands in electric vehicle manufacturing and precision robotics.

Enabling Complex Geometries Without Secondary Operations

Manufacturing Intricate Part Designs in a Single CNC Turning Center Cycle

Multi axis CNC turning centers can handle all sorts of complicated parts features like helical paths and those tricky undercuts right in a single operation cycle. This means no more extra steps or secondary processes needed after the initial cut. According to research from last year, around 89 percent of shops that switched to 5 axis machines saw their rework expenses drop somewhere between thirty to sixty percent. Why? Because these systems position tools at the same time during cutting, which stops those alignment issues that often happen when working through multiple separate steps in traditional manufacturing setups.

Advantages of Multi-Axis Machining for Medical, Defense, and Performance-Critical Components

Multi axis systems have become a must for regulated industries when it comes to machining things like titanium spinal implants where positional accuracy needs to be under 0.005mm, or creating artillery components requiring those super fine micron level surface finishes. Factory floor reports show some big improvements too many top manufacturers are seeing their defense part qualifications speed up around 40% because workers don't have to move parts back and forth between milling and turning stations as much anymore. For medical devices specifically this integrated setup really helps cut down on contamination problems since there's no need to transfer work pieces between different machining areas which can introduce all sorts of unwanted particles into sensitive applications.

Trend: Rising Demand for Organic and Asymmetrical Shapes in Precision Engineering

Aerospace developers now specify 78% more fluid-dynamic turbine blades requiring non-uniform rational B-spline (NURBS) surfacing, while EV battery housings increasingly adopt topology-optimized lattice structures. Modern CNC turning centers meet these challenges with spindle speeds exceeding 12,000 RPM and radial tool access, enabling wall thicknesses under 0.3mm without additional thinning operations.

Integrated Machining: Combining Turning, Milling, and Drilling in One Platform

Maximizing Throughput with Multi-Function CNC Turning Centers

The latest multi axis CNC turning centers combine turning, milling, and drilling all in one machine, which solves many problems that old fashioned setups with multiple machines created. Manufacturers can now get about 85 to 95 percent of their part features done in just one operation according to industry data from 2023. Looking at what's available through the Thomas Supplier Discovery service, we see that these 5 axis systems let shops do contour milling while doing precision turning at the same time. Some real world tests with gear box components showed cycle times dropping as much as 40%. This kind of efficiency makes a big difference for production shops trying to stay competitive.

Eliminating Inter-Machine Transfers to Reduce Errors and Downtime

Moving parts from one machine to another can really mess up the alignment and eats away about 12 to 18 minutes in each operation according to Phas.io research from 2024. The newer generation of CNC turning centers comes with live tools and sub spindles built right in, keeping position accuracy down to around plus or minus 0.005 millimeters even when doing multiple operations in sequence. These systems work as a sort of continuous loop process that stops those little error accumulations from happening over time. They're especially good for making complicated parts without stopping, think hydraulic valve bodies or turbine shafts where precision matters most throughout the whole manufacturing run.

Case Study: Swiss-Type Multi-Axis Machines Producing Complete Surgical Instruments in One Setup

One European company that makes medical devices recently hit an impressive 98% first pass rate when producing those tiny titanium bone screws with built-in hex drives and threaded ends. They did this using these advanced 7-axis Swiss type CNC machines. What makes these machines so special? Well, they have this Y axis milling feature plus counter rotating spindles that handle everything from start to finish. All 23 different manufacturing steps get done in only 11 minutes total. That cuts down on production time quite a bit actually - around two thirds faster than what was possible before with multiple separate machines working together.

FAQ Section

What are multi-axis CNC turning centers?

Multi-axis CNC turning centers are advanced machining systems that can perform various operations such as turning, milling, and drilling in a single setup. These machines are equipped with multiple axes for enhanced precision and the ability to handle complex geometries.

How do multi-axis machines reduce errors in manufacturing?

Multi-axis machines reduce errors by minimizing manual handling and repositioning of parts, which are common sources of misalignment and inaccuracy in traditional machining processes. This ensures better consistency and precision, especially for complex components.

What industries benefit most from multi-axis CNC machining?

Industries such as aerospace, medical device manufacturing, automotive, defense, and precision engineering see significant benefits from multi-axis CNC machining due to its ability to meet high precision requirements and produce complex components efficiently.

Are there cost benefits to using multi-axis CNC systems?

While multi-axis CNC systems have a higher upfront cost, they offer long-term cost benefits by reducing labor costs, scrap rates, and setup times. Most manufacturers can recoup their investment in 18 to 24 months through these efficiency gains.