Superior Rigidity and Vibration Resistance for High-Precision Machining

Structural Advantages of Slant-Bed Over Flat-Bed Lathes for Enhanced Stability

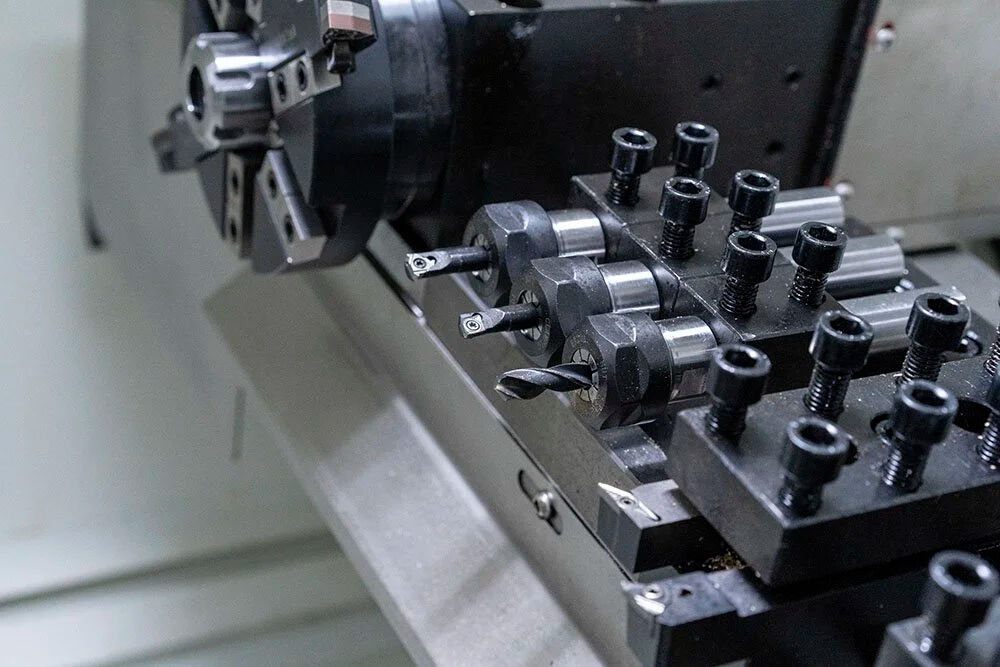

CNC slant bed lathes with their 30 to 45 degree angle offer better structural strength than standard flat bed machines. The angled design creates kind of a triangle shape underneath which helps spread out the cutting force throughout the whole machine base. Flat beds have a problem with tools getting pulled down by gravity over time, but the slanted setup keeps everything aligned properly. This matters a lot when working with really hard materials that are tougher than about 50 on the Rockwell scale. Most machinists notice this difference in performance after just a few jobs.

Thermal Dynamics and Machine Rigidity in Slant Bed Designs Reduce Deformation

Slant bed lathes with precision ground bedways cut down on thermal expansion errors quite a bit actually. Some research indicates these machines experience around 40 percent less positional drift when running nonstop for eight hours straight. The angled setup helps dissipate heat naturally away from important parts of the machine. Better yet, top tier models come equipped with built in cooling channels that keep the bed temperature stable within plus or minus one degree Celsius. All this thermal stability means the machine can achieve really fine level accuracy down to microns. That kind of precision makes all the difference when crafting things like aerospace turbine blades or developing prototypes for medical implants where even tiny deviations matter a lot.

Impact of Reduced Vibration on Surface Finish and Tool Life

When manufacturers reinforce castings in slant bed lathes, they typically see around a 60% reduction in those annoying harmonic vibrations. The result? Surface finishes can get down to below 0.8 microns Ra, which is pretty impressive stuff. The vibration damping also means carbide inserts last anywhere from double to triple what they normally would, especially when working with tough materials like titanium in automotive powertrain components. Less frequent tool changes combined with consistently good parts make these machines stand out in shops that handle lots of different jobs but still need everything to meet tight tolerances day after day.

Higher Processing Accuracy with Minimal Backlash in Ball Screw Systems

Precision and Accuracy of CNC Lathes Linked to Ball Screw Alignment in Slant Beds

Slant bed lathes have this angled design that really helps line up the ball screws properly. When the load travels straight along the workpiece axis, everything just works better. No need for all those complicated gears that flat bed machines require, which means less bending and twisting happens when cutting materials. For shops running at higher speeds, going with preloaded double nut ballscrews makes sense. These components can hold their position pretty accurately, staying within about 0.002mm tolerance even when the spindle spins around 1,500 times per minute. That kind of precision matters a lot in production environments where consistent results are critical.

Minimized Backlash Improves Repeatability in Batch Production

Rigid screw mounting and thermally stable components enable slant bed lathes to achieve â€0.003mm backlash. This level of precision supports ±0.005mm tolerance consistency across production runs exceeding 5,000 parts—critical for automotive camshafts and hydraulic valve bodies requiring long-term repeatability.

X-Axis Travel Advantages in True Slant Bed Lathes Enhance Positional Accuracy

The 45° bed inclination shortens X-axis travel by approximately 30% compared to horizontal layouts, reducing cumulative positioning errors. This geometric advantage allows for 0.001mm resolution on critical diameters, making it ideal for machining interference-prone features such as internal grooves and tapered threads.

Data Insight: 30% Reduction in Geometric Deviation Compared to Flatbed Models

A 2024 machining benchmark study found that slant bed lathes exhibit 30% lower cylindricity deviations when producing 304 stainless steel shafts at 1,200 RPM. Their improved stiffness-to-weight ratio prevents tool deflection during interrupted cuts, maintaining roundness within 0.008mm across all test batches.

Efficient Chip Removal and Debris Management Through Gravity-Optimized Design

Chip Evacuation in Slant Bed Lathes Improves Operational Cleanliness

Slant bed lathes typically have an angle between 30 and 75 degrees which actually works with gravity to help remove chips during machining operations. This solves one of those ongoing headaches for machinists dealing with metal scraps getting stuck everywhere. According to research published last year in Industrial Machining Journal, shops using these angled machines saw their chip clearance speed jump anywhere from 40 to 60 percent compared to traditional flat beds. That translates to roughly 18 fewer minutes spent manually cleaning up after every eight hour workday. The advantages become really noticeable when running large batches of aluminum parts where continuous operation is critical for production schedules.

| Chip Metric | Slant Bed Lathe | Flat Bed Lathe |

|---|---|---|

| Evacuation Speed | 2.5 m/sec | 1.2 m/sec |

| Clogging Frequency | 1/40 hrs | 1/12 hrs |

| Tool Life Preservation | +15–20% | Baseline |

Design Impact on Machining Efficiency and Precision Through Debris Management

By eliminating horizontal surfaces where chips accumulate, slant bed lathes prevent recutting—a major cause of dimensional inaccuracies. This gravity-assisted flow preserves surface finishes down to â€0.8 µm Ra in stainless steel and enhances tool longevity by minimizing thermal contamination from trapped debris.

Comparison: Slant Bed vs. Flat Bed CNC Lathe Design in Aluminum Milling

When machining 6061 aluminum at 3,500 RPM, slant bed lathes achieve a 92% first-pass yield rate, outperforming flat-bed systems at 78%. The continuous chip ejection path proves especially advantageous in unmanned operations, with 87% of manufacturers reporting fewer stoppages due to chip-related issues.

Seamless Automation Integration for Unmanned and Continuous Operation

Automation and Efficiency in CNC Machining via Integrated Part Handling

Modern slant bed lathes support continuous production through robotic part handlers that maintain ±0.002 mm positioning accuracy during high-speed transfers. These systems eliminate manual loading, reducing idle time by 53% (Advanced Manufacturing Report 2023). Dual-arm automated tool changers further enhance efficiency in high-mix environments.

Seamless Integration of Bar Feeders and Chip Conveyors in Slant Bed Layouts

A 45 degree bed angle makes it possible to connect directly with common equipment like bar feeders and those centrifugal chip conveyors most shops already have. The way this setup works is pretty smart actually. It connects everything so smoothly that materials come in while chips go out at the same time, which means factories can switch between different jobs much faster. We're talking about around two thirds less downtime during changeovers when making prototypes for cars. And because chips naturally flow downward along the machine's main line, there's no chance they'll get cut again, something that really matters for maintaining good surface quality on finished parts.

Industry Trend: Unmanned Operation Growth in Automotive Component Manufacturing

Automotive suppliers now run slant bed lathes continuously for over 120 hours in transmission component production. Equipped with pallet changers and IoT-enabled predictive maintenance, these systems achieve 92% equipment utilization and reduce labor costs by 34% (AMT Benchmark 2024).

Cost-Benefit Analysis: High Initial Investment vs. Long-Term ROI in Automated Cells

Although automated slant bed systems require a 25–40% higher initial investment, they typically break even within 14–18 months due to lower scrap and labor expenses. Over five years, operational costs decrease by 48% compared to manual setups, driven by energy-efficient spindles and adaptive cutting algorithms.

Broad Industrial Applications and Future-Ready Adoption in Smart Manufacturing

CNC slant bed lathes have become indispensable across high-tech industries due to their unique combination of precision engineering and digital adaptability. Their rigid construction and advanced control systems position them as critical assets in modern manufacturing ecosystems.

Applications of Slant Bed Lathes Across Industries: Medical, Aerospace, and Defense

Slant bed lathes play a critical role in making surgical tools and parts for implants where the margin for error is incredibly small, sometimes down to just 2 microns. The aerospace industry counts on these machines to create turbine blades with those complicated wing-like shapes, and defense companies need them too for building durable gun barrels that meet strict military specs like MIL-STD-2042. What makes all this possible is how consistently accurate these machines stay during long production cycles, maintaining around plus or minus 0.0002 inches of positioning throughout their operation. When this kind of precision drops even slightly, it can lead to costly rework or worse, safety issues in final products.

Adaptability for Complex Geometries and High-Volume Production Demands

The 30° bed design enables smooth simultaneous X-Z axis movements, ideal for contouring fuel injection nozzles and threading artillery-grade fasteners at scale. In the automotive sector, one electric vehicle manufacturer achieved a 98% first-pass yield on 50,000-unit batches of drivetrain components using this capability.

Future Outlook: Slant Bed Lathes as Key Assets in Industry 4.0 and Smart Factories

As Industry 4.0 adoption accelerates, slant bed lathes are evolving into intelligent production nodes. Modern versions integrate vibration sensors and thermal compensation algorithms that reduce geometric deviations by 27% compared to conventional models (Ponemon 2023). This digital transformation enables 68% faster changeovers when switching between materials like medical-grade titanium and aerospace aluminum alloys.

FAQ

What are the benefits of slant bed lathes over flat bed lathes?

Slant bed lathes offer superior structural strength, reduced vibration, better thermal dynamics, and efficient chip removal due to their angled design, which enhances machining precision and tool life.

How does the angle of the slant bed enhance machining accuracy?

The angle of the slant bed allows for better alignment of ball screws and reduces X-axis travel, minimizing positioning errors and backlash, resulting in higher processing accuracy.

Why are slant bed lathes ideal for industries like aerospace and medical fields?

The precision and rigid construction of slant bed lathes allow them to maintain tight tolerances required for crafting aerospace turbine blades and medical implants, where high accuracy is critical.

What role does automation play in slant bed lathe operations?

Automation allows slant bed lathes to support unmanned, continuous operation with integrated part handling and automated tool changers, enhancing efficiency and reducing labor costs.

Table of Contents

- Superior Rigidity and Vibration Resistance for High-Precision Machining

- Higher Processing Accuracy with Minimal Backlash in Ball Screw Systems

- Efficient Chip Removal and Debris Management Through Gravity-Optimized Design

-

Seamless Automation Integration for Unmanned and Continuous Operation

- Automation and Efficiency in CNC Machining via Integrated Part Handling

- Seamless Integration of Bar Feeders and Chip Conveyors in Slant Bed Layouts

- Industry Trend: Unmanned Operation Growth in Automotive Component Manufacturing

- Cost-Benefit Analysis: High Initial Investment vs. Long-Term ROI in Automated Cells

- Broad Industrial Applications and Future-Ready Adoption in Smart Manufacturing

- FAQ