Understanding the Slant Bed Lathe: Design, Structure, and Key Advantages

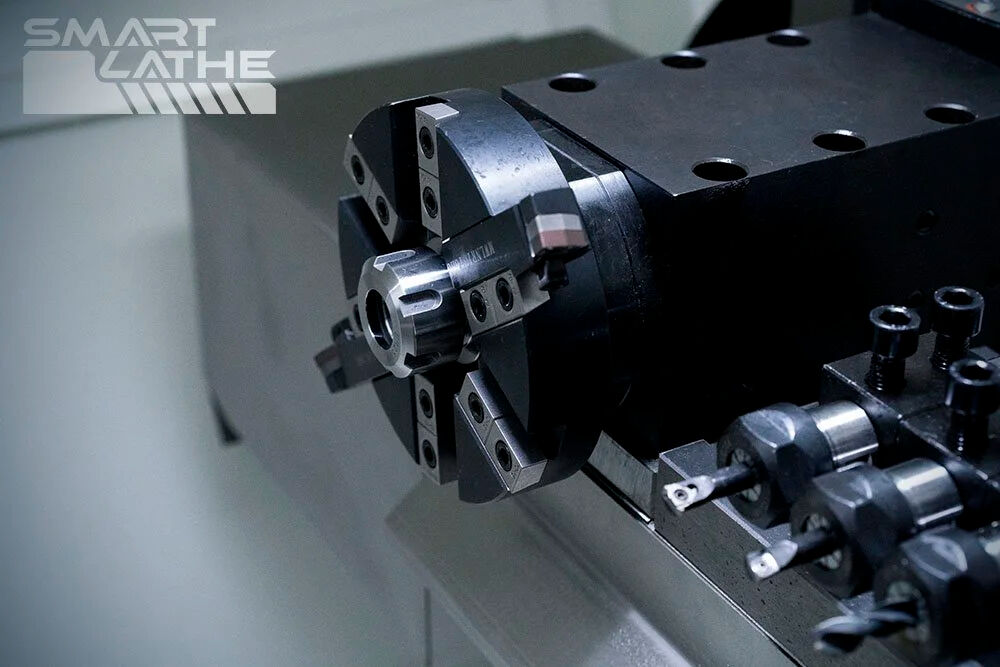

Slant Bed vs. Flat Bed CNC Lathes: Core Structural Differences

What really sets these machines apart is how they're built around the bed angle. With slant bed lathes, parts sit at angles ranging from about 30 degrees all the way up to 75 degrees instead of lying completely flat on traditional horizontal beds. This angled setup actually helps chips fall away naturally under gravity, which cuts down on those pesky recutting problems we see when working with aluminum. According to Machine Tool Digest back in 2023, this can reduce such issues by as much as 85%. Another big plus comes from the triangular shape of slant beds themselves. They offer much better resistance against twisting forces compared to regular flat beds. Some tests show this rigidity improvement hits around 40%, making them especially good for jobs where cutting gets interrupted frequently without losing precision along the way.

45° and 60° Slant Angles with HT300 Cast Iron: Enhancing Rigidity and Stability

Preferred 45° and 60° configurations combine optimized force distribution with high-grade HT300 cast iron bases. This mineral-reinforced material achieves 300 MPa tensile strength, dampening harmonic vibrations by 35% compared to standard cast iron grades. Recent studies confirm 60° beds improve thermal stability by 22% during 8-hour continuous runs, particularly in stainless steel turning applications.

Vibration Damping and Longevity Benefits of Slant Geometry

The slanted layout directs cutting forces axially into the machine base rather than laterally. This mechanical advantage reduces frame deflection to â0.003 mm/meter under full load, extending bearing lifespan by 30â50%. Combined with pre-tensioned linear guides, the design achieves surface roughness values of Ra 0.4 µm even in hardened steels.

Key Performance Gains:

- 50% faster chip evacuation vs. flat beds

- 25% lower machine downtime (4-year operator surveys)

- 18% energy savings through reduced vibration losses

Industry machining studies validate these structural benefits across aerospace and medical device production environments.

Precision Performance: Accuracy and Repeatability in High-Tolerance Machining

Spindle and Feed System Accuracy in Slant Bed CNC Lathes

Slant bed lathes have a natural stiffness that keeps spindle systems accurate to about ±2 microns, even when running heavy cuts for long periods according to recent studies by NIST. What makes this possible? Well, these machines come equipped with built-in feed drive motors along with strong linear guides that cut down on backlash to less than 0.001 inch during complex threading jobs or contour work. Compared to flatbed models where gravity can actually cause some sagging issues over time, the typical 45 to 60 degree angle of slant beds helps prevent axis movement when loads are applied. This means tools stay on track throughout entire production runs, maintaining consistency between parts made at different times.

Thermal Deformation Resistance Through Optimized Frame Design

Modern slant bed lathes equipped with HT300 cast iron frames show around 18% less thermal expansion than regular steel frames when subjected to the same cutting forces. Instead of running coolant channels along outside casings, many manufacturers now route them through internal structural ribs. This design choice helps minimize those pesky temperature differences across the machine that can lead to tiny but problematic dimensional changes at the micron level. The addition of four point contact spindle bearings gives another boost to thermal stability, keeping parts consistently positioned within about 3 microns over an entire 8 hour shift. For shops dealing with tight tolerances day after day, these improvements make a real difference in product quality and machine reliability.

Case Study: Achieving Tight Tolerances in Aerospace Component Production

One major aerospace parts manufacturer cut down rejected hydraulic valve bodies by nearly three quarters when they made the switch to slant bed lathes equipped with active vibration control systems. These advanced machines maintained an impressive 4 micrometer concentricity tolerance while producing Inconel 718 bushings in batches of 300 units straight through without recalibration. That kind of consistency is absolutely essential for getting FAA certification on aircraft components. Looking at what's happening across manufacturing sectors right now, we're seeing similar demands for extreme precision elsewhere too. Medical device makers want implant parts with less than five micrometers variation, and electric vehicle manufacturers are pushing for similarly tight specs on their drivetrain components as well.

Operational Efficiency: Chip Management, Maintenance, and Uptime

Gravity-Assisted Chip Removal in Slant Bed Configurations

Modern CNC lathes typically feature a 30 to 45 degree slant angle that works with gravity rather than against it, helping push metal chips away from where the actual cutting happens. According to data presented at IMTS 2023, this design cuts down on the need for manual chip removal in about 9 out of 10 steel machining jobs, as most of the swarf just drops right into the conveyor belts or collection bins below. Shop floor operators have noticed something interesting too many say their job changeovers go about 38 percent quicker when working with these slanted beds instead of traditional flat ones. The difference comes down to less hassle dealing with leftover bits and pieces getting in the way during setup.

Reducing Downtime and Extending Coolant Life

The chip filtration systems built into slant bed lathes help keep coolants clean by filtering out tiny particles smaller than 50 microns. According to research published last year looking at different ways to handle chips during machining, facilities that combined these filters with automatic cleaning processes saw their coolant last almost 67% longer. Shops are also starting to implement real time checks on coolant thickness, which helps determine when it needs replacing. This simple addition can save anywhere from twelve to eighteen thousand dollars each year just on coolant expenses for average sized manufacturing operations.

Impact on Machine Maintenance Costs and Shop Floor Cleanliness

The slant bed design cuts down on those pesky abrasive chips getting recirculated during aluminum machining operations, which means machine shops replace spindle bearings much less often. Shops that have switched to this setup are seeing around 23 percent fewer slip-related injuries on the floor according to OSHA data from last year, plus workers spend nearly 20% less time each day cleaning up messes. And there's another benefit worth mentioning too. When facilities manage their chips proactively instead of letting them accumulate, electrical cabinets stay cleaner for longer periods. A recent thermal management analysis actually found components lasted almost 30% longer when kept in enclosed systems with good chip control practices in place.

Spindle Capabilities and Material Compatibility for Demanding Applications

Torque and Speed Requirements for Stainless Steel, Titanium, and Composites

Slant bed lathes today need to adjust their spindle capabilities when working with everything from tough stainless steel to those tricky composite materials. When dealing with hardened stuff like titanium at around 60 to 120 meters per minute cutting speeds, manufacturers rely on high torque spindles just to keep that smooth surface finish intact despite all the force involved. Things get different when we switch to carbon fiber reinforced plastics though. These materials call for much faster spindle speeds between 18k and 24k RPM to stop layers from separating during machining while still getting rid of chips efficiently enough not to damage the workpiece. Getting this balance right makes all the difference in production quality across various manufacturing sectors.

| Material | Spindle Speed Range | Torque Demand | Key Challenge |

|---|---|---|---|

| Titanium | 60â120 m/min | High | Heat dissipation |

| Stainless Steel | 80â150 m/min | Medium-High | Work hardening |

| Carbon Fiber | 100â250 m/min | Low | Fiber splintering |

As noted in machining performance studies, slant bed designs enable faster speed transitions while maintaining positional accuracy within ±2 microns.

Thermal Management During Continuous Cutting Operations

A slant bed setup at around 45 to 60 degrees helps get rid of heat better because it stops hot spots from forming around important parts. When machines have liquid cooled spindles along with frames that stay balanced in temperature, they barely deform at all â we're talking under 5 microns after working for eight hours straight, even with tough materials like nickel alloys. The newer cooling tech with two separate circuits cuts down on how much coolant is needed by about thirty percent compared to old school flood cooling methods. And best part? The cutting tip stays cool enough, under 650 degrees Celsius, even during those really intense rough cuts that push equipment to its limits.

Selecting the Right Slant Bed Lathe: Matching Machine to Application and Future Needs

Evaluating Part Complexity, Precision Requirements, and Production Volume

When looking at parts for machining, dimension and shape complexity matter a lot. Parts smaller than 300mm across usually work best with slant bed lathes. Take hydraulic valve bodies as an example these need super tight tolerances. Machines that can hold position within 5 microns or better according to JIS B6336 standards really cut down on wasted time and money from having to fix mistakes later. According to research from the Ponemon Institute back in 2023, around seven out of ten manufacturing shops handling small batch sizes below 500 pieces went with slant beds because they make switching between different jobs so much faster. Meanwhile big volume manufacturers stick mostly to automated flat bed systems since they just want maximum output without worrying about frequent tool changes.

Total Cost of Ownership: Balancing Upfront Cost and Long-Term Productivity

| Cost Factor | Slant Bed Lathe | Flat Bed Lathe |

|---|---|---|

| Initial Investment | $120kâ$300k | $80kâ$180k |

| Tool Change Savings | $740k/5 yrs | $320k/5 yrs |

| Scrap Rate Reduction | 3.1% average | 1.7% average |

Though slant beds cost 20â40% more upfront, their 35% faster cycle times and 60% lower chip-related downtime (Okuma 2022 benchmarks) typically yield ROI within 18 months for mixed-material production.

Future-Proofing with Scalable Controls and Automation Readiness

Leading manufacturers now embed IIoT-ready controls supporting OPC UA integration for seamless robotic loading integration. A medical device maker recently achieved 94% lights-out machining by pairing 45° slant bed lathes with modular pallet changersâa configuration projected to dominate 38% of the precision components market by 2026 (ABI Research).

Growing Adoption in EV and Medical Device Manufacturing Sectors

The electric vehicle boom has really pushed demand for slant bed lathes up by around 54% each year, especially when it comes to making those battery terminals. These machines with their thermal stable HT300 cast iron beds can hold tight ±0.002mm tolerances even while slicing through aluminum alloys at high speeds. Meanwhile over in the medical manufacturing sector, companies are seeing validation cycles speed up by nearly 30% thanks to AI tools that optimize cutting paths on those 60 degree slant beds used for titanium spinal implants. This actually lines up pretty well with what the FDA put out in their 2023 rules about needing traceable precision in medical device production. Makes sense since both industries need rock solid accuracy but for slightly different reasons.

FAQ Section

What is the main advantage of a slant bed lathe over a flat bed lathe?

The primary advantage of a slant bed lathe is its angled design, which allows chips to fall away naturally under gravity, reducing recutting issues and improving rigidity and precision.

How does the slant angle in a lathe impact its performance?

Slant angles, particularly 45° and 60°, enhance force distribution and improve thermal stability, contributing to more effective vibration damping and increasing the lifespan of bearing systems.

What materials are best suited for machining with a slant bed lathe?

Slant bed lathes are excellent for tough materials like titanium, stainless steel, carbon fiber composites, and Inconel, owing to their precision and capacity to handle high torque and varied spindle speeds.

How does chip management differ in slant bed lathes?

Slant bed lathes utilize gravity to assist in chip removal, significantly reducing the need for manual intervention and extending coolant life, thereby improving overall operational efficiency.

Are slant bed lathes more cost-effective in the long run?

While slant bed lathes involve a higher upfront cost, they offer significant long-term savings through improved cycle times, reduced downtime, and increased tool life, leading to faster ROI.

Table of Contents

- Understanding the Slant Bed Lathe: Design, Structure, and Key Advantages

- Precision Performance: Accuracy and Repeatability in High-Tolerance Machining

- Operational Efficiency: Chip Management, Maintenance, and Uptime

- Spindle Capabilities and Material Compatibility for Demanding Applications

- Selecting the Right Slant Bed Lathe: Matching Machine to Application and Future Needs

-

FAQ Section

- What is the main advantage of a slant bed lathe over a flat bed lathe?

- How does the slant angle in a lathe impact its performance?

- What materials are best suited for machining with a slant bed lathe?

- How does chip management differ in slant bed lathes?

- Are slant bed lathes more cost-effective in the long run?