Structural Rigidity and Mechanical Stability in Slant Bed Lathe Design

How slant bed geometry enhances structural integrity and load distribution

CNC lathes benefit greatly from the triangular structural foundation formed by their slant bed geometry. When we look at actual performance numbers, these machines show about 18 to 22 percent better rigidity than standard flatbed models. Plus, they cut down on vibrations during fast operations by roughly 40%. The angled surface works wonders for directing cutting forces straight into the machine's base. This means less stress builds up in those important parts, sometimes reducing it by as much as 40%. For real world applications, this translates to keeping positional accuracy within just 0.002 mm even when dealing with heavy loads over 8 kilonewtons. Flatbed designs usually drift between 0.005 and 0.008 mm under similar workloads, making slant beds clearly the better choice for precision work.

Angle configurations (30°, 45°, 60°) and their influence on stiffness and accessibility

How steep the slant bed is makes a big difference in how solid the machine feels and how easy it is to work on. Most shops find that angles somewhere around 30 to 45 degrees work really well because they cut down on vibrations without making chips get stuck anywhere, plus tools can reach what needs doing. The 45 degree setup has become pretty standard across many workshops since it balances stability with ease of use. Some manufacturers go for 60 degrees when they need extra strength for tough jobs though. Going steeper actually brings the whole machine closer to the ground, which helps keep things steady even when cutting at higher speeds something that matters a lot in production environments where downtime costs money.

Alignment of cutting forces with gravity for reduced deflection and vibration

When the cutting tool is angled downward, it works better with gravity instead of fighting against it. This means most of the force gets transferred straight down into the machine base rather than creating twisting stress points. At higher speeds over 4,500 RPM, this setup cuts down on vibrations quite a bit – around 40% less shaking compared to standard designs. The benefit? Operators can take bigger bites out of materials without losing track of where they are cutting. Parts come out consistently sized with smoother surfaces too. For factories running thousands of identical pieces day after day, getting this kind of repeatable quality makes all the difference between good products and rejects.

Advanced Motion Systems Enabling High-Speed Precision Machining

Linear guide rails and pre-loaded ball screws enable rapid, accurate tool positioning with minimal backlash, forming the core of modern slant bed lathe motion systems. These components ensure micron-level precision (±0.002 mm) and maintain rigidity even during aggressive cutting cycles involving frequent direction changes.

High-Performance Spindle Drives and Direct-Drive Integration

High-torque spindle motors in modern slant bed lathes can achieve speeds of 10,000 RPM or higher while maintaining thermal stability. Direct-drive integration eliminates belts, gears, and other transmission elements, reducing mechanical losses and vibration. This allows instantaneous power delivery, improving surface finish quality during acceleration and deceleration phases.

CNC Motion Control Achieving Micron-Level Accuracy at High Speeds

Modern CNC systems rely on smart algorithms that manage multiple axes simultaneously while adjusting for inertia as it happens. These machines are equipped with high precision encoders that constantly send back information, allowing them to make tiny corrections that keep parts accurate down to fractions of a micron even when running at full speed. Such precise control makes all the difference when creating intricate shapes that need to fit together perfectly in industries where automation reigns supreme. Manufacturers across various sectors depend on this capability to meet demanding specifications without compromising quality or efficiency.

Balancing Spindle Speed, Acceleration, and Sustained Precision

Optimizing high-speed performance requires balancing spindle speed, acceleration profiles, and cutting forces to prevent tool deflection while maximizing efficiency. Modern control systems dynamically adjust parameters based on real-time load conditions, ensuring consistent dimensional accuracy and surface finish throughout extended machining cycles.

Precision Accuracy Under Thermal Load and Dynamic Conditions

Thermal stability in slant bed lathes during prolonged high-speed operation

Keeping things cool matters a lot when machines run at high speeds for long periods. Heat causes parts to warp, which creates most of the consistent errors we see in precision work. Slant beds have that angle built into their design, so heat spreads out more evenly over important parts. This design actually fights off warping pretty well. Machines stay accurate even after hours of operation when temperatures climb. Shops that rely on tight tolerances find this feature especially valuable because it means fewer rejects and less downtime fixing warped parts later on.

Minimizing thermal drift through symmetrical design and material selection

To tackle thermal drift issues, many manufacturers turn to symmetrical frame designs paired with materials that expand very little when heated. The symmetry helps distribute heat evenly throughout the machine, which keeps things dimensionally stable during operation. Research indicates that when thermal management is done right, machining accuracy can jump as much as 60 percent over setups where temperature control is neglected. For industries working on precision parts like aerospace components or medical devices, getting this balance right makes all the difference between acceptable tolerances and costly rejects.

Maintaining tight tolerances and surface finish in complex turning tasks

Modern slant bed lathes keep their precision down to the micron level even when temperatures start climbing, all because they come equipped with these thermal compensation systems built right in. The systems watch for changes in heat as they happen and tweak where the tools go so surfaces stay smooth enough for really detailed work. We're talking finishes that hit below 0.4 microns roughness average, which matters a lot when making parts for planes or medical devices where there's simply no room for error. For shops working on components that need to meet those tough specs, this kind of stability makes all the difference between passing inspection and having to scrap whole batches.

Sustained dimensional accuracy in high-volume production environments

In continuous 24/7 production, advanced slant bed lathes maintain dimensional accuracy within ±0.002 mm over long runs. Optimized cooling systems and thermal shielding limit heat buildup, enabling sustained precision. As a result, manufacturers achieve part conformity rates as high as 99.8%, demonstrating the effectiveness of modern thermal management strategies.

Efficient Chip Evacuation and Integrated Thermal Management

Slant bed geometry promoting natural chip flow and preventing buildup

A slanted bed functions like a gravity feed system that really helps with managing metal chips during machining. When compared to flat horizontal beds where chips tend to pile up right next to where the cutting happens, these angled designs usually set at around 30 to 60 degrees actually push those chips away from what's being worked on. Getting rid of this chip buildup stops something called recutting which wears down tools way too fast and leaves bad surface quality on parts. For shops running at high speeds with lots of automation, proper chip removal becomes absolutely essential when dealing with all that material coming off during production.

Reducing heat accumulation through optimized chip removal

Getting rid of chips fast is really important for keeping things cool during machining operations. When those hot metal scraps get pulled away from where the cutting happens, it cuts down on how much heat gets transferred into both the part being worked on and the machine itself. Good chip removal makes all the difference when it comes to keeping dimensions stable over time. Some research suggests that managing chips properly can cut thermal distortion somewhere around 35-40 percent, which means manufacturers can hold tighter tolerances throughout extended production cycles without worrying so much about warping or other heat-related issues messing up their parts.

The role of coolant systems and thermal shielding in maintaining precision

The shape of the machine helps chips move away during operation, while active cooling systems take care of leftover heat buildup. When running at speed, high pressure coolant does double duty cooling down where the tool meets the workpiece and washing those pesky chips off the machine bed before they cause problems. Thermal shields are another important part of keeping things stable, especially around delicate parts such as spindle bearings and ball screw assemblies that can't handle much heat exposure. All these different approaches working together mean slant bed lathes stay within tight temperature ranges needed to produce parts with extremely accurate dimensions even when pushing through long production runs at higher speeds than traditional setups allow.

High-Performance Tooling and Real-World Applications of Slant Bed Lathes

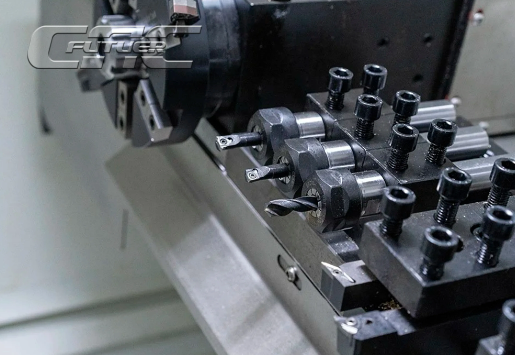

Modern slant bed lathes feature advanced tooling systems such as multi-station turrets and automatic tool changers (ATCs), enabling rapid, hands-free tool swaps. Some configurations achieve change times under one second, minimizing downtime and supporting fully automated, continuous production cycles.

Case study: Spindle performance under continuous 10,000 RPM operation

Testing showed that when running a slant bed lathe at 10,000 RPM for three straight days, it performed really well. The temperature stayed pretty stable with only a 2 degree Celsius fluctuation, and the position measurements didn't drift much either, staying within 0.001 mm accuracy the whole time. What this means is that the machine can keep going at top speed without losing its precision, which matters a lot in factories where downtime costs money and quality control is everything. For shops that need reliable results day after day, this kind of consistency makes all the difference.

Industry adoption in aerospace, medical, and smart manufacturing

The slant bed lathe has become a staple in sectors where getting things just right matters most. The aerospace industry depends heavily on these machines when crafting turbine blades and landing gear components that need to meet those incredibly strict dimensional specs. For medical device makers, these lathes are essential in producing surgical instruments and implantable devices where even the smallest surface irregularity can mean the difference between success and failure in clinical settings. What makes slant bed lathes stand out is how well they work within modern production environments. Many facilities now connect them to internet-based monitoring systems that track machine performance continuously. This connection allows technicians to spot potential issues before they become problems and fine tune operations as needed throughout the day.

FAQs

What are the benefits of the slant bed lathe design?

Slant bed lathe designs offer enhanced structural integrity, better load distribution, and reduced vibrations, which result in improved precision and surface finish quality.

How does the angle of a slant bed lathe affect its performance?

The angle influences the machine's stability and ease of access for tooling. An angle of 30° to 45° provides a good balance, while steeper angles like 60° offer increased strength for demanding tasks.

How do thermal management strategies in slant bed lathes improve accuracy?

Advanced thermal management, including symmetrical designs and optimized cooling systems, minimizes thermal distortion and drift, ensuring accurate machining even under thermal loads.

Why is chip evacuation important in slant bed lathes?

Efficient chip evacuation prevents recutting and reduces heat accumulation, which in turn maintains part quality and extends tool life in high-speed machining applications.

Table of Contents

- Structural Rigidity and Mechanical Stability in Slant Bed Lathe Design

- Advanced Motion Systems Enabling High-Speed Precision Machining

- Precision Accuracy Under Thermal Load and Dynamic Conditions

- Efficient Chip Evacuation and Integrated Thermal Management

- High-Performance Tooling and Real-World Applications of Slant Bed Lathes

- FAQs