Understanding CNC Turning Centers: Types, Configurations, and Core Capabilities

What Is a CNC Turning Center? Key Differences from a CNC Lathe

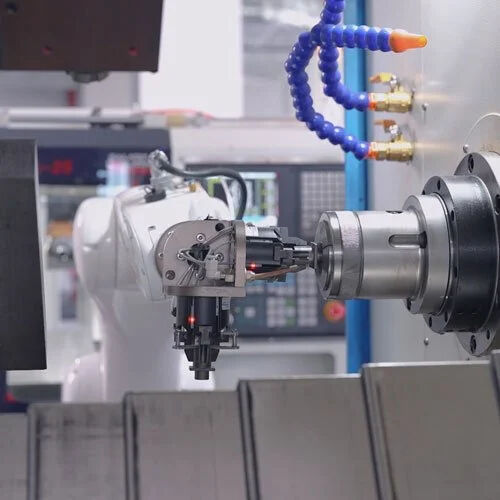

CNC turning centers represent a step up from regular CNC lathes because they combine rotational cutting with live tooling features. These machines can actually do milling, drilling, and threading too something standard lathes just cant handle. The main difference lies in how they work. Both types spin the workpiece against cutting tools, but turning centers go further by allowing multiple axis movements and additional processing steps all within one machine setup. This saves time on production lines where efficiency matters most.

| Feature | CNC Lathe | CNC Turning Center |

|---|---|---|

| Axes | 2-axis (X,Z) | 3—5 axes + Y-axis option |

| Tooling | Fixed turret | Live tools, sub-spindles |

| Complexity | Simple geometries | Multi-surface machining |

| Automation | Manual part handling | Robotic integration ready |

This expanded functionality reduces setup changes by 65% in high-mix production environments compared to conventional lathes.

Horizontal vs. Vertical CNC Turning Centers: Strengths and Use Cases

Most shops rely on horizontal turning centers for about 78% of their regular machining work because they handle chips so well and work great with those automatic bar feeders. Things change when we look at vertical machines though. These bad boys find their home mostly in aerospace and energy industries where they tackle big, thick parts such as turbine disks. Gravity actually helps hold everything steady here, which makes a real difference when cutting with high torque forces. Some tests showed this can boost performance around 40%. A recent industry report from last year found something interesting too. Nearly 92% of medical implant manufacturers use vertical turning centers specifically for creating those super precise components that need concentricity down to the micron level.

How Machine Configuration Impacts Machining Speed, Accuracy, and Part Complexity

The number of axes determines geometric capability:

- 3-axis: Standard turning and milling

- 4-axis: Off-center drilling using C-axis rotation

- 5-axis: Complex contours such as orthopedic joint surfaces

Turret capacity influences automation efficiency 12-station turrets allow completion of 85% of automotive brass fitting jobs without manual intervention. Spindle power (15 50 HP) and torque must match material properties; mismatched configurations increase tool wear by 300% when machining hardened steel versus aluminum.

Matching CNC Turning Center Features to Your Production Requirements

Assessing Material Types, Part Sizes, and Tolerance Demands by Industry

Parts used in aerospace applications need to stay stable when heated so they can keep those super tight tolerances around 0.0005 inches, according to NIST research from last year. Car makers tend to focus on producing lots of aluminum parts at once, aiming for smooth surfaces around 32 microinches roughness average. When it comes to medical devices, companies making tiny implants under 2 millimeters usually rely on special machines called Swiss type lathes working with materials that won't harm body tissues. What industries actually need ends up shaping what kind of machine spindles work best. Take Inconel 718 for instance, this tough metal needs anywhere between 30 to 50 percent extra spinning power compared to regular steel during machining operations.

Precision, Surface Finish, and Efficiency in High-Tolerance Machining Environments

Getting sub-micron level accuracy happens when machines use linear motor drives along with hydrostatic guideways. These components cut down on geometric errors by around 62 percent when compared to older ball screw systems according to SME research from 2022. When it comes to creating those mirror smooth finishes needed for parts like hydraulic cylinders, servos that can resolve movements under 0.1 microns work best when paired with adaptive damping technology. This combination really helps keep vibrations at bay and prevents annoying tool chatter problems. The addition of high pressure coolant running at over 1,000 psi makes a big difference too. Tools last about 40% longer when working with hardened steel materials, and surfaces stay pristine even after long production runs without interruption.

Live Tooling and Y-Axis Integration: Expanding Capabilities Beyond Turning

Machines with 12 station live tooling turrets can actually produce complicated components such as camshafts all in one go, which cuts down on production time significantly around 30% maybe even more, and also slashes positioning mistakes by about half give or take. The Y axis capability lets these machines handle things like side milling, drilling at angles, and shaping contours too, so there's no need for extra steps when making cross holes or keyways. For sectors such as oil and gas this really matters because most valve bodies need both turning and milling work done together. According to Frost & Sullivan research from last year, roughly four out of five valve bodies fall into this category requiring those combined machining processes.

Real-World Example: Reducing Secondary Operations with Multi-Tasking Machines

One medical device company managed to slash their production process for stainless steel biopsy needles down from seven steps to just two after implementing a multi-tasking turning center equipped with C-axis contouring and those handy opposing spindles. The switch saved them around $18.50 per part and boosted concentricity measurements by about 0.002 inches, which makes all the difference when trying to hit those tight FDA standards for sterility. Their new setup features a robust 15kW main spindle along with live tools spinning at 10,000 rpm. This allows continuous operation producing well over 20,000 units each month with an impressive first pass rate hovering near 99.98%. Such performance levels are becoming increasingly important as manufacturers face growing pressure to maintain quality while keeping costs under control.

Selecting the Right CNC Turning Center Provider: Support, Service, and Training

Why Vendor Expertise Matters Beyond Machine Specifications

The way machines perform over time really hinges on how good the vendor is at getting the most out of them. Vendors who've been around for 15 years or more cut down on setup mistakes by about 40 percent when compared to regular equipment sellers according to SME research from last year. These experienced folks know all the tricks of the trade for specific industries. Take aerospace work where they deal with super tight tolerances on titanium parts, or medical devices that require certain surface finishes. Top tier vendors actually send engineers to help solve real world problems. Sometimes materials act differently than expected, or tools might collide during operation. Specialists working with turbines have figured out ways to set up cutting parameters for Inconel 718 ahead of time, which means fewer wasted test runs overall. Their hands-on experience just makes everything run smoother in practice.

Evaluating Warranty Terms, Technical Support Response, and Training Programs

When shopping for machine tools, make sure the warranty covers those essential parts like spindle bearings and ball screws for at least three years. Why? Because downtime can cost about $480 every single hour according to AMT's latest numbers from 2024. Technical support matters too. Shops that work with companies able to provide video help within four hours see their machines running longer. Around 87% of them actually report better results this way. The amount of training makes a real difference in how things turn out. Operators who go through full certification programs lasting over 80 hours tend to get first pass yields around 92%, whereas folks with just basic training only hit about 68%. Smart manufacturers should look for training options that break down into modules covering important areas such as CAM programming, getting live tools to sync properly, and understanding how IoT systems predict when maintenance is needed before breakdowns happen.

Case Study: Choosing a Partner for High-Mix, Low-Volume Production Success

A medical device contractor reduced secondary operations by 53% after partnering with a supplier specializing in rapid job changeovers. The vendor implemented zero-point pallet systems and conducted on-site Y-axis programming clinics. Within six months, annual output increased by 320 parts without additional labor, delivering a 19% ROI improvement.

FAQ

What are the main differences between CNC turning centers and CNC lathes?

CNC turning centers differ from CNC lathes in that they combine rotational cutting with live tooling features, allowing for milling, drilling, and threading. They support multiple axis movements and additional processing steps within one machine setup, leading to enhanced functionality compared to standard lathes.

When should a manufacturer choose a vertical CNC turning center over a horizontal one?

Vertical CNC turning centers are most suitable for industries like aerospace and energy that deal with large, thick parts. They offer stability due to gravity-assisted cutting, which is beneficial when working with high torque forces and achieving high precision.

How does machine configuration affect machining speed and accuracy?

The configuration, such as the number of axes and turret capacity, directly impacts geometric capability, automation efficiency, and machining speed. The precision of machining processes depends on choosing the right spindle power and torque according to material properties.

What should be considered when selecting a CNC turning center provider?

One should consider the vendor's industry expertise, warranty terms, technical support response time, and available training programs. Experienced vendors provide better setup efficiency and can offer solutions to real-world machining problems.

Table of Contents

- Understanding CNC Turning Centers: Types, Configurations, and Core Capabilities

-

Matching CNC Turning Center Features to Your Production Requirements

- Assessing Material Types, Part Sizes, and Tolerance Demands by Industry

- Precision, Surface Finish, and Efficiency in High-Tolerance Machining Environments

- Live Tooling and Y-Axis Integration: Expanding Capabilities Beyond Turning

- Real-World Example: Reducing Secondary Operations with Multi-Tasking Machines

- Selecting the Right CNC Turning Center Provider: Support, Service, and Training

-

FAQ

- What are the main differences between CNC turning centers and CNC lathes?

- When should a manufacturer choose a vertical CNC turning center over a horizontal one?

- How does machine configuration affect machining speed and accuracy?

- What should be considered when selecting a CNC turning center provider?